How Do A-Frame BTEX Systems Improve Air Quality in Oil and Gas Facilities?

When you manage or work in an oil and gas operation, you notice air quality issues long before someone brings it up in a meeting. You can smell the VOCs on a warm day. You can see how quickly equipment vents build up residue. You watch your team work around emissions that shouldn’t be floating in the air in the first place. That’s usually when you start looking for something proven, not experimental.

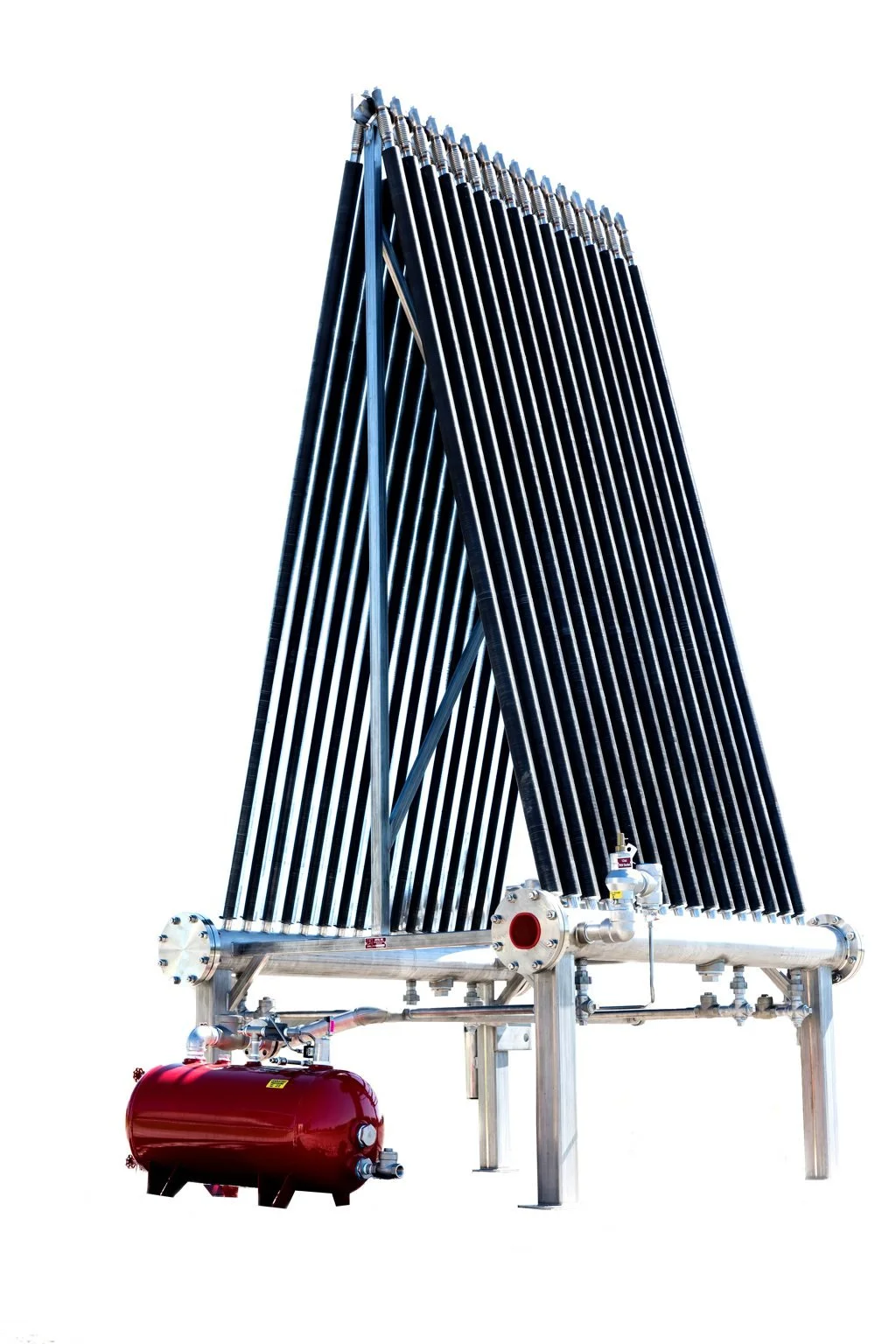

This is where A-Frame BTEX systems make a real difference. They’re not fancy. They’re not complicated. They just work. And when you’re dealing with BTEX compounds that evaporate fast and travel far, you need something that’s both simple and reliable.

From what we’ve seen in facilities over the years, you feel the improvement once these systems go in. You don’t guess. You see it.

Why BTEX Control Matters for You

BTEX compounds are benzene, toluene, ethylbenzene, and xylene. You work around them every day, whether you think about it or not. They escape through separators, tanks, and lines that look sealed but aren’t as sealed as you think.

When BTEX levels rise, you deal with:

More odor complaints

More regulatory attention

More wear on your team

More long-term risk around your site

And if you’ve ever had to stop production to deal with an emissions issue, you know how fast those hours add up.

A good control system reduces that pressure. A great one removes it.

How A-Frame BTEX Systems Actually Improve Air Quality

Most systems that manage BTEX rely on vapor recovery or flaring. Those options have their place, but they’re not always consistent. A-Frame systems take a different approach. They condense vapors using a proven cooling process so you can recover the liquids before they drift into the air.

Here’s what that looks like in practice.

1. They pull BTEX vapors out before they escape

In a typical setup, vapors rise into tanks and vent hardware. With A-Frame BTEX systems, those vapors are captured earlier. They’re pulled into a controlled path where the system can manage them properly.

When you remove vapors at the source, you reduce what reaches the atmosphere. And you stop chasing problems after they’ve already happened.

2. The cooling design increases recovery

The A-Frame shape isn’t cosmetic. The angled layout increases surface area, which improves cooling. Cooler metal equals more vapor condensation. Condensed BTEX becomes liquid again, which means it stays in your system instead of entering the air.

You get cleaner air around your tanks and a measurable reduction in emissions coming off the equipment.

3. They run with very low failure rates

These systems don’t rely on complicated electronics or components that need constant calibration. Most facilities run them with minimal oversight. Some units work for years with only small routine checks.

You already know how valuable low-maintenance equipment is. Anything that stays consistent without constant supervision buys you time and keeps your operation smoother.

4. They help you stay ahead of regulations

Regulations around BTEX emissions aren’t getting lighter. Each year the limits shrink. If you wait until you’re close to a violation to fix the problem, it’s already too late.

A-Frame systems help you show visible, measurable control.

Lower vent VOC readings

Fewer odor issues

Better compliance reports

Stronger environmental audits

When inspectors see reliable hardware running efficiently, the entire conversation shifts in your favor.

5. They protect the people who work in your facility

You can’t always see BTEX exposure. But your team feels it when levels rise. Better air quality means fewer headaches, fewer complaints, and better morale.

A-Frame systems don’t eliminate every emission on-site. Nothing does. But they make a noticeable dent in the VOC load your team works around every day.

What Most Facilities Don’t Realize

When you install a strong BTEX control system, you don’t just improve compliance. You stabilize production. You reduce downtime. You reduce heat stress around tanks. You avoid unplanned shutdowns caused by venting limits.

These improvements add up fast. Many operators underestimate how much BTEX emissions hurt their day-to-day workflow until they finally see a system that removes the problem.

When You Should Consider an A-Frame BTEX System

You should think about adding one if you’ve noticed any of these issues:

Higher vapor readings around your tanks

More venting than usual

Complaints from workers about air quality

Flaring systems running more often than you expect

Regulators are asking more questions than they used to

If any of this sounds familiar, BTEX control is already affecting your operation.

A Quick Note About JATCO

If you’re looking for experience you can trust, this is where we’ll point you toward JATCO. We’ve been building this equipment long enough to know what works and what fails in real field conditions. You get straightforward systems, built for real use, not lab demonstrations. When you want something reliable, you go with builders who’ve done it for decades.

Conclusion

A-Frame BTEX systems improve air quality because they capture vapors early, cool them efficiently, and keep those emissions inside your process instead of in the air. They support compliance, reduce downtime, and protect the people working on your site.

If you care about stronger environmental solutions for oil and gas, this is one of the simplest and most proven upgrades you can make.

A quick summary:

They reduce BTEX emissions at the source

They cool and condense vapors efficiently

They require low maintenance

They support regulatory compliance

They improve working conditions

Better air quality isn’t just a goal. With the right equipment, it becomes part of how your facility operates every day.

Stronger environmental solutions for oil and gas always start with proven tools that work the same way in every season.

FAQs

1. How much maintenance do A-Frame BTEX systems need?

They only need simple routine checks and very little ongoing care.

2. Do A-Frame BTEX systems reduce VOC levels?

Yes, they noticeably lower vapor readings around tanks and vents.

3. Can they handle high vapor loads during peak production?

Yes, the cooling design manages heavier vapor flow without problems.

4. How fast will I see air quality improvement?

Most sites notice cleaner readings and less odor within a few days.